With recent developments in automation and machine learning, robotics has increasingly made its way into various sectors, helping to maximize efficiency and productivity.

In land surveying, robotics growth is on the rise, and the industry stands to change dramatically thanks to the many versatile applications of survey robots. However, many surveying teams still experience challenges in georeferencing the collected data so that it can be used for meaningful mapping and analysis.

Fortunately, the capabilities of survey robots can be enhanced across the board when used with Real-Time Kinematic (RTK) positioning. From land-based survey robots to RTK-enabled drones, the possibilities of RTK applications for survey robots are nothing short of extraordinary.

What is robotic surveying?

Land surveying has long been a critical part of engineering and development. Without a deep understanding of the 3D positions of points, land development is impossible. In the 21st century, there is a transformation underway with the advent of robotic surveying.

Robotic surveying refers to the use of automated systems equipped with advanced technologies to perform various survey tasks. These “survey robots” are designed to operate autonomously, reducing the need for direct human involvement.

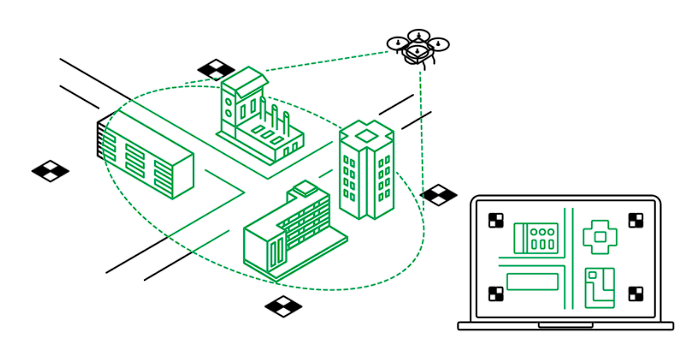

Mapping, drone path planning, and topographical surveys are all tasks that survey robots can handle.

How Survey Robots Work

Survey robots leverage sensors, cameras, and advanced navigation systems to navigate and collect data. Survey robots have a variety of applications, all of which require location precision. If the robot’s task is to place something into the correct location or to map an area, pinpoint precision is requisite.

Generally, when survey robots rely on traditional GPS alone, they face a limitation in precision, as GPS on its own is accurate at the meter level. Correcting errors in GPS has historically been a time-consuming process.

But when paired with a GNSS correctional method like RTK, survey robots are capable of centimeter-level precision. This is particularly crucial for applications where precise spatial data is essential.

RTK systems ensure that the robot’s position is precisely determined, thereby giving way to a host of advancements in environments such as construction sites and land surveying projects.

Advantages of Using Robots in Surveying

The integration of survey robots into traditional surveying processes offers unparalleled advantages:

Higher Efficiency

Survey robots, empowered by RTK, redefine efficiency in surveying. The integration of RTK technology results in faster, more accurate data collection and surveying processes, optimizing the overall workflow.

Of course, the efficiency of your RTK system depends on your setup. If you’re trying to build your own RTK, you’re going to run into ongoing maintenance, calibration, updates, and troubleshooting–all leading to higher costs, technical challenges, and a lot of time and headaches.

The best solution is working with affordable RTK services like Point One Nav have already perfected the technology. A dedicated solution like Point One’s Polaris offers unparalleled location precision without sacrificing quality and efficiency.

From the easy-to-use platform to the incredible cost-effectiveness, surveyors will have immediate access to a dense network of base stations that integrate seamlessly with existing protocols. This means that Point One takes care of the setup and management, avoiding costly downtime, reliability concerns, and convergence times.

With Point One, you can access:

- The highest overall density of U.S. RTK corrections networks

- Extra RTK base station redundancy in urban centers (top 50 cities in the US all have over 4 stations)

- An easy-to-expand RTK network driven by customer demand

- High-accuracy GNSS corrections with delivery over satellite, even in areas without cellular coverage

- 99.99% uptime of the RTK corrections network

All for just $60 a month.

Learn more about Point One Polaris

Location Precision

Precision is the cornerstone of effective surveying. RTK technology elevates location precision to unprecedented levels, ensuring that every data point is captured with meticulous detail, providing surveyors with a reliable foundation for their analyses, and allowing them to navigate much more complicated terrain.

Furthermore, the advanced technology and precision of RTK provide both absolute and relative survey data so that surveyors understand the land geospatially, as well as relative to nearby objects on the site.

Take, for example, a construction site layout. Both absolute and relative location precision are crucial during the layout and positioning of structures in construction sites, ensuring accurate placement of foundations and taking into account existing structural elements.

If you are determining land parcel boundaries for property surveys, meticulous location precision is essential. RTK provides real-time corrections to the constellation so that precise spatial information is available at your fingertips, whether you work in urban planning or infrastructure inspection.

Greater Productivity

With survey robots picking up a significant amount of labor, survey teams can now focus on data analysis and decision-making. This is even further enhanced by RTK systems like PointOne, as there is less of a need for oversight of the survey robots.

For example, while traditional GPS runs a risk of drone collision, with the centimeter-level accuracy achieved by adding RTK to your GNSS, drone collisions are a thing of the past. This leads to increased productivity as the time previously spent on oversight can be reallocated.

Plus, since drones and survey robots enabled with both GPS and RTK can instantly georeference a single image and correct GPS signal inaccuracies in real time, you no longer need to wait hours for your data to be corrected.

Instead, you can instantly download your images and data and construct a map. Productivity is drastically improved by pairing survey robotics and RTK.

Flexible Navigation

Navigating diverse terrains is a challenge that survey robots equipped with RTK technology can achieve with ease. Take, for example, a swamp or a densely populated urban area. Survey robots are built to adapt to diverse and often challenging environments.

Equipped with advanced sensors and navigation technologies, these robots can navigate through construction sites, uneven terrains, or areas with obstacles, adjusting their paths and movements based on real-time data. Notably, survey robots are often equipped with obstacle avoidance systems and sensors that can detect obstacles in their path and adjust accordingly.

With RTK, this ability improves exponentially. While traditionally, local site surveys have been time-consuming endeavors, survey robots using RTK can navigate any terrain with tremendous precision. This gives land surveyors a versatile tool that enhances navigation possibilities like never before.

Safety for Survey Teams

Land surveyors are often the first to navigate new terrain, which can lead to unexpected hazards. In fact, those in the fields of construction and agriculture make up many of America’s most dangerous jobs. Fortunately, robotics provides ample opportunity to reduce risk by employing survey robots with these tasks.

Survey robots provide an opportunity to reduce risks by giving the robots the task of navigating hazardous or hard-to-reach areas, reducing the risk of any construction accidents. For example, survey robots could complete projects on busy highways or high-traffic areas.

Survey robots can be used to reduce risk in underground mines, irrigation, and dense urban areas. Rather than eliminating the need for surveyors, it shifts the industry toward a new skillset. Surveyors can oversee, manage, maintain, analyze, and interpret the data obtained from robots, maximizing the brainpower of your team and leaving dangerous tasks to the survey robots.

How Robots Are Used in Surveying

Whether at a construction site, a mine, a swamp, a farm, or a densely populated urban area, the use of robotics in surveying has many applications and stands to bring tremendous economic growth to the field.

Land Surveying

In land surveying, robots equipped with RTK technology can cover large areas autonomously, collecting accurate data for mapping and analysis. The use of RTK ensures that the collected data is georeferenced with high precision.

Furthermore, the capabilities of robotics include the ability to record thermal data and land stability and provide atmospheric readings in addition to more traditional measurements. This means that not only would land surveying happen more quickly but there would be more data for surveyors to analyze.

With the unparalleled centimeter-level accuracy and precision provided by RTK, mapping an area can be done without significant processing time, making survey robots an incredible asset for reality detection. For example, when mapping a mine, a survey robot equipped with RTK could determine the exact size of a pile of coal. The georeferencing possibilities of mapping with robotics and RTK significantly enhance the field.

Though robots and drones may be tasked with data collection, surveyors will still be needed to set control, detail structures, and program the flight path.

Construction

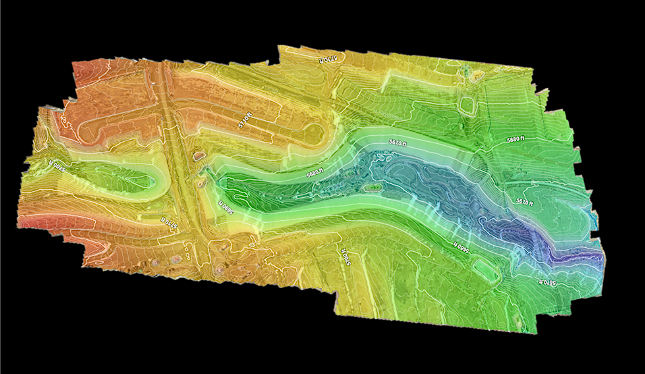

A sample of the 3D model using RTK surveying was created as marketing content for his client, a real estate firm opening a new mixed-use development.

In construction, robotic surveying has provided significant benefits. Survey robots can navigate construction sites, monitor progress, and ensure that structures are built according to precise specifications. This level of accuracy is crucial for large-scale construction projects.

Survey robots are also able to complete construction tasks that might put workers at risk. The US Bureau of Labor Statistics reported workers in construction had the second most fatalities of all professional fields. Robotics offers the possibility of remote operation, and when paired with RTK, the precision is so reliable that it greatly reduces the likelihood that workers need to put themselves in risky situations.

When equipped with RTK corrections, survey robots provide unparalleled reality detection for construction sites. They can also conduct progress detection for construction sites, enabling accurate monitoring of the project development over time. This ensures that deviations from the plan can be promptly identified and corrected, reducing the risk of costly construction delays and rework.

Damage Prevention & Risk Analysis

A sample of a topographic map generated from RTK-enabled LiDAR data collection.

Survey robots can be deployed to safely venture into areas prone to natural disasters or potential hazards. Equipped with advanced sensors and navigation systems, survey robots can autonomously navigate hazardous terrains, collecting real-time data that aids in risk assessments.

By identifying potential risks and vulnerabilities, survey robots assist in preventive measures and timely interventions, preventing damage. Whether we’re talking about assessing the stability of structures, monitoring environmental conditions, or evaluating the impact of geological factors, survey robots provide valuable insights into potential dangers.

Survey robots provide a proactive solution to damage prevention and risk analysis so that you are aware of how your structure might be affected by, say, flooding. This type of risk analysis aids greatly in safety and reduces costly damages.

Mapping

Maps are necessary in a variety of sectors but are central to surveying. However, some areas can be extremely difficult to map. In mapping applications, survey robots equipped with RTK contribute to the creation of detailed and accurate maps, especially in difficult terrains. For anyone making a map with drones, the use of RTK greatly enhances the mapping accuracy.

While drones equipped with GPS can complete mapping, achieving spatial accuracy with those images requires significant post-processing time. This is because of the accuracy limitations of GPS, which typically provide meter-level accuracy.

However, using location precision technology like Point One Polaris increases GPS accuracy exponentially. Point One Polaris provides best-in-class RTK solutions and services and unparalleled customer support, providing surveyors with the tools they need to achieve centimeter-level accuracy in mapping–for just $60 a month.

What Do Survey Robots Cost?

Investing in survey robots involves considering a range of factors. Historically, robotics has come at a steep price, leading to a slow rate of adoption in surveying and construction.

In fact, only 55% of construction companies across the US, Europe, and China were using robotics in 2022, according to ABB Robotics.

However, though robotics can be pricey, we’ve seen those prices drop as automated production becomes more popular. Over the past 30 years, the average robot price is half of what it once was–and this does not account for the additional savings in decreased labor costs that survey robots provide.

In addition to the initial investment cost, it is important to consider the ongoing maintenance and support. For many, it can be tempting to build your own RTK system after shelling out money on robotics. However, while this solution may seem desirable at first, the time to set up and manage base stations is a hefty endeavor. The ongoing maintenance costs of building your own system will make this seemingly affordable option less desirable.

Fortunately, there are affordable, high-quality dedicated solutions on the market such as Point One Polaris. Point One’s user-friendly platform with robust API and a dedicated customer service team allows surveyors to get straight to work without any costly setup or troubleshooting, maximizing productivity.

Improve Robotic Survey Accuracy

Leveraging RTK for georeferencing data collections provides an added layer of confidence to survey results. RTK ensures that the robot’s position is meticulously determined by comparing its location using base stations and rovers.

Ultimately, this empowers survey robots to navigate and capture data with unprecedented precision.

To enhance the accuracy of robotic surveying, look no further than Point One’s RTK technology. Point One’s Polaris network provides GNSS corrections to drones and survey robots worldwide.

Overcoming the limitations of standard GNSS systems, Polaris leverages compact base stations and FusionEngine software to reduce position uncertainty caused by factors like atmospheric signal delay and satellite orbit variation.

With a network of more than 1,440 global base stations, this comprehensive network supports all major GNSS constellations and navigation signals, offering precise location data for a variety of applications, including autonomy, robotics, precision agriculture, logistics, and industrial automation. With the robust GraphQL-based API, anyone can seamlessly integrate Polaris RTK into their applications, facilitating rapid deployment and maximizing compatibility and performance across devices.

With Point One Polaris, surveyors can produce maps with hundreds of times more accuracy and can navigate terrain with greater precision than ever before. Whether you are in construction, land surveying, or agriculture, your drones and robots have a far greater capacity to serve your business with RTK.

Chat with a Point One expert